Essential Strategies for Balancing Work and Life in Construction

Editorial Note: This article was brought to you courtesy of Rose Morrison, managing editor of ...

It’s that time again—the start of a new year, when many make resolutions. We view the start of the year as the opportune moment for you to take a look at your inventory operations, assess, and put into work the important changes that will ensure a better outlook for the coming year.

We’ve previously written about the importance of inventory in the New Year (e.g., inventory best practices 2022, inventory management best practices 2021), so for regular readers, some of our tips may serve as a refresher—however, these time-tested traditions remain critical as talent is harder to come by, construction costs rise, etc. What’s more, we’ve added a couple new ones to the list to keep our new and returning readers on your toes.

But before we get started, here are a few relevant statistics to inspire and kickstart your 2023 business:

Now, let’s jump into those construction inventory practices to deploy in the new year!

In a world of big data, fictional tech CEOs theorize extreme scenarios, like “datageddon”—however, these humorous examples of cultural satire are not that far from reality.

Anyone with an iPhone can attest to the dreaded “iCloud storage almost full” messages, and for businesses, duplicate data entry is often the culprit behind serious data inefficiencies, which often perpetuate the same real-world problems that digital solutions were supposed to correct (e.g., upending data loss from shuffling papers in a busy tool crib). That is to say, even aided with technology, human error is still there. Human error can result in inaccurate statistical results and conclusions—as pointed out by researchers at the University of Nevada-Las Vegas and Keiser University in their 2011 paper, published in the peer-reviewed academic journal Computers in Human Behavior. “A single data entry can make a moderate correlation turn to zero and a significant t-test non-significant,” the authors wrote. Despite being a 12-year-old research paper, the problems presented therein remain accurate today—furthermore, as industries like construction are finally laying down the infrastructure needed to digitize, tool manufacturers and software developers are teaming up to bring solutions such as software integrations that will help reduce manual inputs, synchronize data, and drive efficiency.

Duplicate data entries have become a problem ubiquitous of the digital age, felt simultaneously by customers and service providers. Almost any business in virtually every industry can attest to having to deal with duplicate data at some point—whether that’s the consumer product brand struggling to find “a single customer view,” the marketing team struggling to send out relatable emails, or customers corresponding with your service team encountering a disjointed experience (or a combination of them all).

Duplicate data entries have become a problem ubiquitous of the digital age, felt simultaneously by customers and service providers. Almost any business in virtually every industry can attest to having to deal with duplicate data at some point—whether that’s the consumer product brand struggling to find “a single customer view,” the marketing team struggling to send out relatable emails, or customers corresponding with your service team encountering a disjointed experience (or a combination of them all).

Closer to home, tool and equipment inventory duplicates are also a serious problem we find happening, and it usually starts at the onset. For example, when users add a 1/2” Drill/Driver, the naming conventions used the first time may not match up as they add additional items of this same kind, or as other inventory managers in the crib are added and start managing the flow of new items.

The result may be multiple items with similar, albeit slightly different, names: e.g., Milwaukee 1/2” Drill/Driver, Milwaukee 1/2 Drill, Milwaukee 1-inch drill, Milwaukee Fuel 1-inch drill, etc.

When it comes to duplicate data issues, the unfortunate scenario you may face is that there may be more upfront work before the true impact is felt.

![]()

That said, correcting old, recurring problems by implementing the right infrastructure to prevent them in the future is key.

Potential solutions:

Organization in the digital world doesn’t excuse disorganization in the physical world.

We’ve previously written about the importance of tool crib organization.

Did you know that using the correct organization tools can improve time management by 38%? Or that a manager loses 1 hour a day to disorder? Miscommunication and poorly documented project data, meanwhile, accounts for 52% of rework, an Autodesk/FMI-joint survey found.

Just as we previously discussed of the importance of laying the right infrastructure down for data entry, organizing the physical world within the tool crib is an important first step to ensuring the digital world where important equipment information (e.g., tool transfers, assignments, location history, etc.) can be managed without incident.

Tool kitting is an important inventory practice used by crib and tool room managers in order to group (in bulk) a job’s tool and equipment, create and audit a list of these received items on the job, and offer the ability for field ops teams to sign-off (or request more information, report a discrepancy, etc.) on these items in real-time.

Tool kitting is a live feature that anyone can use in ONE-KEY™ for free:

Choosing the right tracking hardware to assign to your items is a critical part of maintaining visibility and the smooth flow of inventory to the job, as well as ensuring tool managers can keep track of these items while keeping costs down.

![]()

Put another way: The right tracking hardware helps you ensure the right stuff ends up on the right job at the right time, so work can commence on schedule—and also that these items find their way back to the crib when the job finishes.

Just as the adage “you need the right tool for the job” rings true for proper electrical installations, rough-in plumbing, etc., the right tracking tool is needed for a successful job.

Here are our recommendations:

| Job | Tool of Trade |

|

Small tool tracking (e.g., low-value items such as hand tools like screwdrivers, hammers, etc.; ladders; job carts; etc. |

Asset tagging (or barcoding) offers basic scan-in/out functionality. Barcoding is typically used in warehouses and can be extremely useful to update basic inventory information, like tracking safety stock levels, for example. Possible solution: · ONE-KEY™ Asset ID Tags offer construction-grade durability (intended to last the life of the tool) that solve the typical problem of traditional barcodes that wear out and fall off—they also provide easier scanability via a 3D matrix code, the ability to ditch the expensive barcode equipment (the One-Key app uses your smartphone camera), and a location update with every scan. |

|

Tool tracking of medium-to-high value items (e.g., individual power tools like drills, saws, etc.) |

Bluetooth® tagging offers more advanced BLE tracking via a crowd-sourced tracking community. Combined with our industry-leading tracking network, contractors and tradespeople can connect sites, people, and equipment via industry-leading tracking hardware: · ONE-KEY™ Bluetooth® Tracking Tag. This recent product replaces our legacy TICK™ Tool & Equipment Tracker and adds additional tracking technology, including built-in NFC and a scannable QR code for simplier activation, an onboard accelerometer providing greater equipment location data (e.g., item “last-used”), a built-in speaker for in-vicinity item finding, 3X Bluetooth range compared to the previous product. Furthermore, this product has been very well-received, winning both a Pro Tool Innovation Award and Chicago Innovation Award. · Milwaukee® Tool ONE-KEY™ compatible smart power tools. It may be worth it to upgrade your inventory to smart tools. Milwaukee offers the widest range of smart tools and equipment, which come standard with Bluetooth tracking, as well as (depending on the item) the ability to dial in precision controls for application-specific accuracy and repeatability, the ability to pull tool utilization data and reporting, etc. |

|

Equipment/Asset tracking for high-value items and equipment (e.g., expensive generators, heavy machinery, fleet vehicles) |

GPS (global positioning system) tracking offers the most advanced and real-time (i.e., to the moment) equipment location data on the market—however, it also comes at a usually higher cost (e.g., think higher equipment costs, subscription fees, etc.). That’s why we usually recommend reserving GPS trackers for your most valuable inventory items. This might be the fleet vehicles that transport all your inventory, the job boxes containing large quantities of inventory on the job, your costly heavy machinery, etc. |

Safety stock, we’ve previously defined, is the “extra quantity of supplies or resources deliberately set aside as a precaution against events that can’t otherwise be planned for—e.g., the “buffer” or “reserve” stock that will cushion against a number of different situations that could lead to you running out of items in your inventory (aka: “stockout”).

Businesses understand the importance of safety stock. For example, did you know that over half of warehouses plan to expand the number of inventory SKUs carried over the next five years (Motorola via Capterra).

While labor shortages are hard to address (we have added some tips on how to be competitive among jobseekers), inventory may help negotiate these challenges. After all, if large tech companies can make job cuts to look “lean” to investors on paper, why can’t the opposite be true, to work smarter with the talent you do have.

Safety stock, when combined with a good construction inventory management system, can offer added capabilities. For example, taking a look at equipment location history, pulling utilization data, or looking into an item’s historical service records are a few examples where a tool room manager can begin to make data-driven insights to find answers to important inventory-related questions like “should I repair or replace my tools?” before a breakdown occurs. In fact, automated service reminders can ensure something like that doesn’t happen. What’s more, equipped with this data, your tool team can start to implement performance-improvement inventory KPIs like order lead time, labor utilization, asset turnover, return on assets, etc., to start tracking toward better profitability each year.

We’ve previously written about the advantages to integrated software in place of the so-called “one-off” solution.

Software integrations play an important role in both:

Despite the importance of software integration, for many companies it’s an uphill battle.

Some startling statistics about the lack of software integration that exists among organizations:

At Milwaukee, we consider data & integration as an important attribute of what makes an inventory app great, and we use this as one of our “4 fundamental pillars” that define how we develop our app. Example integrations include Autodesk BIM 360 and Procore.

However, we also regularly offer technology partnership opportunities, pilot programs, and we’re regularly seeking opportunities to build new integrations that help facilitate enhanced productivity and drive our industry forward. One of our product managers recently joined the Construction Progress Coalition, for example, to help participate in important dialogue among construction leaders about potential solutions for future technologies. You can even stop by Oracle’s industry lab to see our torque wrench reporting experience in action in through an immersive experience, and chat with us about a potential partnership.

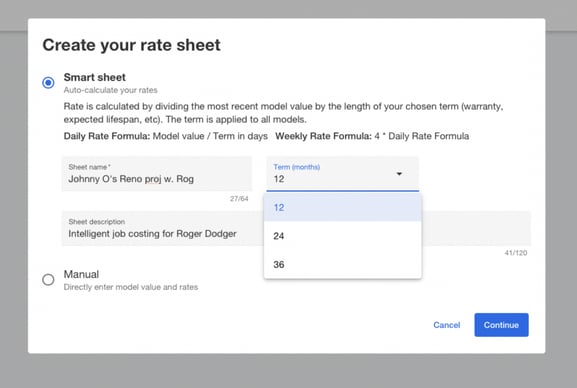

Construction job costing is an important business process that describes the proactive steps taken to track the associated costs and revenue of a given project throughout its lifecycle.

A couple key equipment rental statistics showing the importance of job costing:

Job costing in construction inventory management helps tool managers calculate rates for the tools they’re sending to the job, and manage this process from the cloud via a suite of job costing/reporting tools.

The One-Key app recently rolled out a job costing feature, free to use! It’s important to note, too, that while job costing is usually an enterprise feature used by large construction companies, anyone can take advantage of this feature, especially sole proprietors and scrappy entrepreneurs looking to leverage digital tools to take their business to the next level.

The job costing feature in the One-Key app enables users to:

Construction inventory management allows contractors and tradespeople alike to more seamlessly manage the jobs they’ve taken on by allowing them to maintain visibility to, for example, their tools and equipment (of various manufacturers), service, documentation, etc.; utilize barcode scanning and tracking hardware; manage jobsite communications from a central, cross-device interface; manage places and subcontractors; etc.

Milwaukee Tool offers a free construction inventory app that offers numerous benefits and features, including:

In this white paper, learn 5 advantages of digitizing your construction inventory in the cloud. Increase productivity, limit downtime, & more.

2023 is officially here! And while labor/productivity challenges persist, the above-mentioned construction inventory management strategies for 2023 can help you work smarter with an agile tool team.

Sign up to receive ONE-KEY™ news and updates.

Editorial Note: This article was brought to you courtesy of Rose Morrison, managing editor of ...

Editorial Note: This article was brought to you courtesy of Rose Morrison, managing editor of ...

Editorial Note: This article was brought to you courtesy of Rose Morrison, managing editor of ...