There’s a whole alphabet soup of inventory management methods to choose from if you’re a construction pro looking for better ways to organize your mission-critical tools, materials, and equipment.

One of the simplest inventory management methods—outside of ONE-KEY™— is something called “XYZ analysis.”

Key Takeaways

-

XYZ analysis is an inventory management method that organizes items based on their demand.

-

In construction, XYZ analysis is best used for gaining insight into the flow of consumables ordered in bulk that are more difficult to track on an individual basis.

Jump Ahead

What is XYZ Analysis?

XYZ analysis is an inventory management method that classifies items based on the variability and predictability of their demand.

As a bulit-in capability of many Enterprise Resource Planning (ERP) programs, contractors and construction managers can use XYZ analysis to systematically determine how much of an item to order and keep in-stock to meet the demands of present and future building projects.

XYZ analysis approaches the question of inventory management through the lens of demand forecasting: What is the level of demand for each inventory item? How much does demand for each item change over time? And what do those fluctuations in demand tell us about which items we should prioritize over others?

XYZ analysis provides a framework for reliably forecasting answers to those questions, empowering businesses to make smart, data-based inventory management decisions now about the short and long-term future of their enterprises.

XYZ analysis in construction Inventory Management

Composed of multiple segments, a typical construction inventory includes everything from large-scale equipment and electrical power tools to small hand tools and consumables. And that’s not even mentioning building materials.

Keeping track of all these segments requires a variety of inventory management strategies.

For larger items with long lifespans, your best bet is to use a tool tracking app like One-Key (more on that in a moment).

XYZ analysis may be best suited for organizing consumables and other items with relatively shorter lifecycles that are purchased in bulk according to their SKUs.

How Does XYZ Analysis Work?

XYZ analysis ranks each inventory item into three categories (X, Y, and Z) according to the frequency and predictability of demand for that item.

X — fixed demand (20% of items)

Items that are constantly used and are therefore in consistent demand. With steady turnover over time, future demand for “X” items can be reliably forecast with high accuracy.

An example of an “X” item in a typical construction inventory would be common consumables like drill-bits or razor blades—items that are frequently used and worn-out at a steady rate, and whose demand can therefore be reliably forecast.

Y — fluctuating demand (30% of items)

Items that are used at an unsteady rate and therefore have moderate fluctuations in demand. Though turnover of “Y” items is typically driven by known factors such as seasonality and product lifecycles, it is nevertheless more difficult to forecast future demand for these items.

An example of a “Y” item in a typical construction inventory might include heated gear—items that are necessary, but whose demand is tied to unsteady fluctuations in weather.

Z — uncertain demand (50% of items)

Items that are only occasionally used. Following no predictable pattern, demand for “Z” items is sporadic and unexpected, making forecasts of future demand very difficult.

An example of a “Z” item in construction might be an extremely rare and highly-specific type of decorative screw or other vintage finishing items used exclusively in specific historical renovation projects.

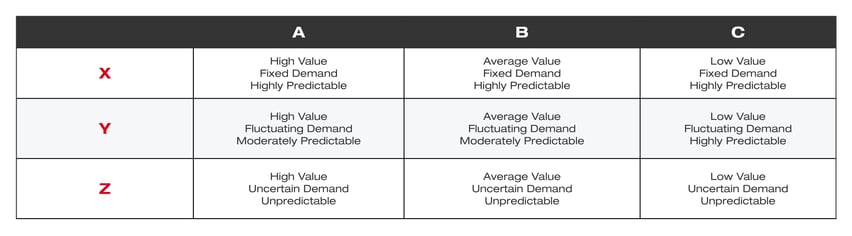

ABC Analysis and XYZ Analysis

XYZ analysis is an extension of ABC analysis, a well-known strategy for organizing inventory items according to their value.

Rooted in the Pareto Principle (otherwise known as the 80/20 rule) ABC analysis holds that about 20% of the items in an inventory hold 80% of the inventory’s total value.

Where ABC analysis is good at identifying the worth of inventory items, XYZ analysis fills in the gaps by modeling how fluctuations in demand effect an item’s availability and priority level over time.

Combining the two methods enhances a business’ ability to make smart spending and inventory management decisions that factor in an item’s present and future value and level of demand.

5 Benefits of XYZ Analysis

Lost, stolen, or simply mismanaged materials and assets can result in lowered productivity and profitability for your business.

Inventory management methods like XYZ analysis provide a systematic framework that can deepen your understanding of how your own inventory works and help reduce errors that come at a high cost of time, money, and productivity.

Save Money

A staggering $1.1 trillion is lost every year due to poor inventory management practices, according to estimates by global research firm IHL Group. A lot of that waste is generated by stockouts and overstocks that tie up capital and constrict cashflow. By spotlighting the varying levels of demand among items in your inventory, XYZ analysis can help you make smart spending decisions about what items to order, when to order them, and precisely how much stock you should keep on hand.

Improve Forecasting

XYZ analysis enables you to forecast fluctuations in your inventory and build in appropriate responses before there’s need for a costly emergency stock replenishment. By putting reliable material and asset demand data at your fingertips, XYZ analysis makes it possible to take proactive measures now for the future of your business instead of waiting to react when a crisis occurs.

Reduces Stockouts

Your most used assets are also the ones that are most likely to wear out the fastest, increasing the risk that you will run out of them at an inopportune time. Running out of an item is called a “stockout.” XYX analysis can help ensure that stockouts never occur by identifying your most used items and providing highly accurate forecasts of their future demand.

Reduce Waste

Overstocks can be just as costly as stockouts. Storage space is valuable real estate, and having too much of a certain item can equally lead to difficult and expensive choices about what stays and what goes. XYZ analysis can help your business reduce waste and embody lean principles by establishing a just-in-time approach that ensures there is never too little or too much of any item within your inventory at a given time.

Increase Turnover

High turnover is a strong indicator that you are effectively using the items in your inventory to generate money for your business. XYZ analysis can help drive high turnover by ensuring that your most used items are always properly deployed instead of gathering dust on a shelf somewhere.

The Milwaukee Connection

The free One-Key app by Milwaukee® creates a digital storage space for all of your physical tools, allowing multiple users to access pertinent documentation and location information for entire inventories from the screen of their computer or mobile device. The app comes with a broad range of unique features, including community Bluetooth tracking, and remote tool lockout.

One of One-Key’s primary functions is inventory management.

Some of the app’s features that might complement an XYZ analysis include:

- Inventory Audit: Run a quick scan of a location to check on which tools are in the area.

Learn more about “How Construction Pros Can Streamline Inventory Audit with One-Key”

- Tool Transfer: Seamlessly track and organize your tools as they move from one jobsite to the next.

- Tool Kitting: Organize your tools into separate kits for specific projects and jobsites.

- Add Categories and Subcategories: Get granular by organizing your tools into specific categories and sub-categories.

- Job Costing: Capture data about how much you’re paying to rent tools and equipment.

Bottom Line

XYZ analysis is a simple technique for organizing inventories according to the demand of each item. Combining XYZ with ABC analysis can reveal a more detailed picture of how an item’s value and demand interact to affect the availability of that item over time. With benefits ranging from financial savings to increased turnover, XYZ analysis is one of many inventory management tools that construction professionals can use to keep better track of their most valuable assets.

References

- MERİMA, B. (2021). ABC/XYZ Inventory Management Model in a Construction Material Warehouse. Alphanumeric journal, 9(2), 325-334.

- Nowotyńska, I. (2013). An application of xyz analysis in company stock management. Modern Management Review, 18(20 (1)), 77-86.

- Pandya¹, B., & Thakkar, H. (2016). A review on inventory management control techniques: ABC-XYZ analysis. REST Journal on Emerging trends in Modelling and Manufacturing, 2(3), 2016.

- Trubchenko, T. G., Kiseleva, E. S., Loshchilova, M. A., Dreval, A. N., Ryzhakina, T. G., & Shaftelskaya, N. V. (2020). Application of ABC and XYZ Analysis to Inventory Optimization at a Commercial Enterprise. In SHS Web of Conferences (Vol. 80, p. 01007). EDP Sciences.