Wood that you can see through. A shade of paint that cools buildings. Living concrete that repairs itself. Once the stuff of science-fiction, these and other high-tech materials are poised to revolutionize our struggle against climate change.

One of the most effective strategies for making construction more sustainable is to change the materials we build with. Shifting away from carbon-intensive steel and concrete toward naturally-abundant renewable materials like mycelium and hemp is a good start. Science, however, has given birth to a variety of high-tech materials that can boost construction even further down the path of sustainability, opening up novel ways to make our buildings more energy-efficient and less environmentally destructive.

In this article, we’ll take a look at five high-tech building materials dreamt up in the lab that promise a greener tomorrow for the construction industry.

- The World’s Whitest Paint

- Chameleon Skin

- Self-Healing Concrete

- Solar Glass

- Transparent Wood

The World’s Whitest Paint

Imagine being able to cool a building simply by putting a coat of paint on it.

This is the promise of the world’s whitest paint, unveiled in 2021 by researchers at Purdue University. The paint—created with a blend of light-scattering barium sulfate particles—is so glaringly white that it’s capable of reflecting more than 98% of the sunlight that hits it, keeping buildings up to 19 degrees Fahrenheit cooler at night.

The creation has set a Guinness World Record and won numerous awards, including the South by Southwest (SXSW) 2023 Innovation Award in sustainability and recognition by the 2023 Gizmodo Science Fair.

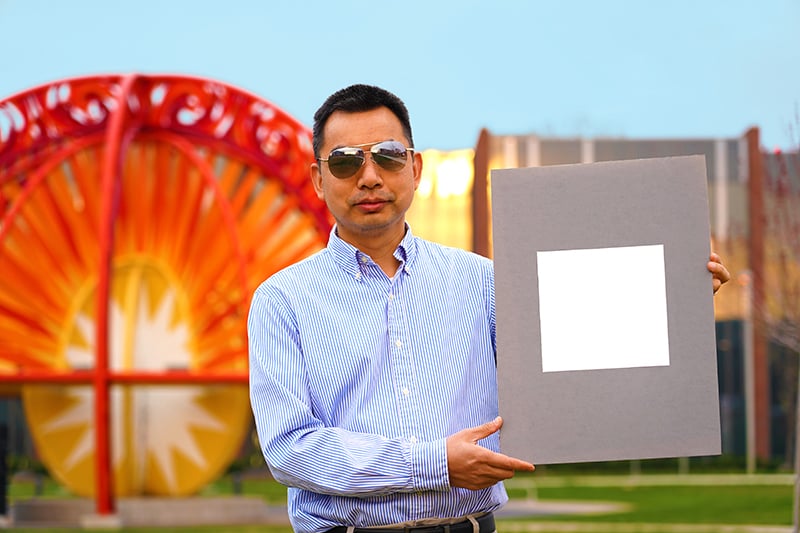

Xiulin Ruan is the Purdue professor who spearheaded the project. According to him, conventional white paint from the hardware store only reflects roughly 80 to 90% of light. Buildings painted with his team’s ultra-white paint, he claimed, could potentially eliminate the need for air conditioning.

Xiulin Ruan, a Purdue University professor of mechanical engineering, holds up his lab’s sample of the whitest paint on record. (Purdue University/Jared Pike)

Here’s Ruan in a recent interview with Smithsonian Magazine:

“Air conditioners can cool your house, but they move the heat from inside the house to outside—the heat is still in the city, it’s still on the Earth. Our paint does not use any power, but, more importantly, it sends the heat to space. The heat doesn’t stay on the Earth, so that really helps the Earth to cool down and can stop the warming trend.”

Cities in hotter climates are already using light shades of paint to cool the urban heat island effect. New York City, for example, has begun painting the roofs of buildings white. Meanwhile, Los Angeles, CA; Phoenix, AZ; and Abu Dhabi, UAE are painting their streets with a product called CoolSeal in an attempt to beat the heat.

The ultra-white paint from Purdue isn’t yet available to consumers, but Ruan says he and his team are working with manufacturers to get the product on shelves ASAP.

Chameleon Skin

Here’s another material that can help regulate the temperature of buildings, this time by changing color and morphing from a solid into a liquid.

Researchers at the University of Chicago’s Pritzker School of Molecular Engineering have developed an ultra-thin electrochromic film modeled after chameleons. Incapable of generating their own body heat, chameleons regulate their temperatures by changing the pigmentation of their skin, taking on dark hues to absorb sunlight when they need to warm up and lighter shades to deflect it when they need to cool down.

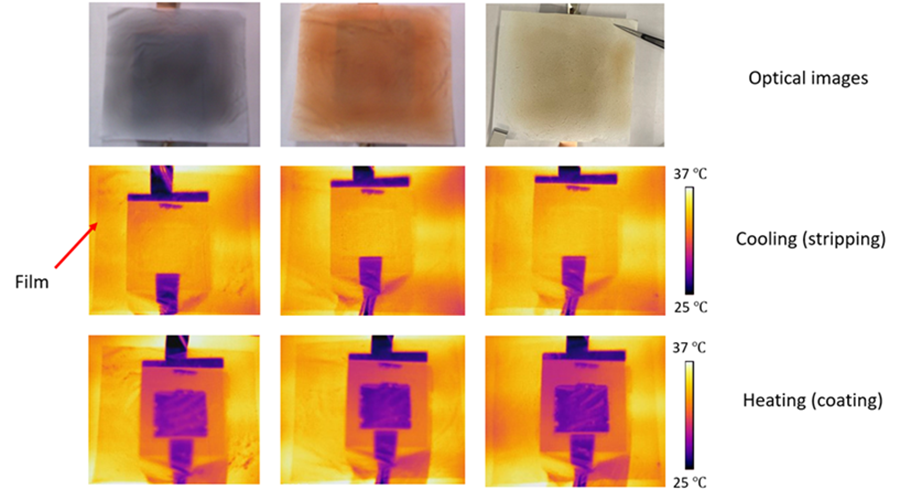

The electrochromic film developed by Assistant Professor Po-Chun Hsu and his team of researchers follows the same principle: Sensing and responding automatically to outside temperatures, the material can switch between two infrared states, each of which has a different effect on the interior temperature of the building. When it’s cold out, the material morphs into a solid copper state that absorbs heat. When it’s hot out, the material will shift into a liquid state that instead deflects heat.

The material contains a layer that can take on two conformations: solid copper that retains most infrared heat, which helps keep the building warm; or a watery solution that emits infrared, which can help cool the building. (Image courtesy of Hsu Group)

A very small amount of electricity is used to induce this chemical transformation. The researchers found that in an average commercial building, the material would require less than 0.2% of the structure’s year-to-year electricity and could save roughly 8.4% on annual HVAC energy consumption.

“We’ve essentially figured out a low-energy way to treat a building like a person; you add a layer when you’re cold and take off a layer when you’re hot,” said Asst. Prof. Po-Chun Hsu, who led the research published in Nature Sustainability. “This kind of smart material lets us maintain the temperature in a building without huge amounts of energy.

“If we want a carbon-negative future,” Hsu said, “I think we have to consider diverse ways to control building temperature in a more energy-efficient way.”

As of this writing, the chameleon material can only be produced in small batches, in pieces that measure roughly six centimeters across. If Hsu and his team can successfully scale up their creation, you may someday be able to purchase chameleon shingles and siding at your local hardware store.

Self-Healing Concrete

This next high-tech building material hails from ancient times.

Self-healing concrete is exactly what it sounds like: Concrete that can repair itself from cracks, damage, and other forms of erosion.

Traditional concrete is strong, but it isn’t without its drawbacks. As one of the most common building materials of the modern era, concrete has an enormous carbon footprint, accounting for about 8% of CO2 emissions worldwide. What’s more, for all its strength and durability, modern concrete tends to break down, placing the lifespan of even steel-reinforced concrete within the range of 50 to 100 years.

This might seem like a long time until you realize that many ancient unreinforced concrete structures like the dome of the Roman Pantheon remain standing more than 2,000 years later. How is this possible?

The answer is self-healing concrete. Now, all forms of concrete have some amount of “self-healing” power: even in conventional concrete, hairline cracks and fissures are able to partially mend themselves due to the ongoing hydration of innate clinker materials, for example. But the self-healing ability of modern concrete pales in comparison to the cementitious stuff of ancient times. Roman engineers “hot mixed” their concrete with quick lime in a unique process that scientists at MIT recently identified as the key to the resiliency of structures like the Pantheon. Water entering into cracks reacts with the quick lime, forming calcium-rich deposits called “lime clasts” that fill the cracks and re-strengthen the structure.

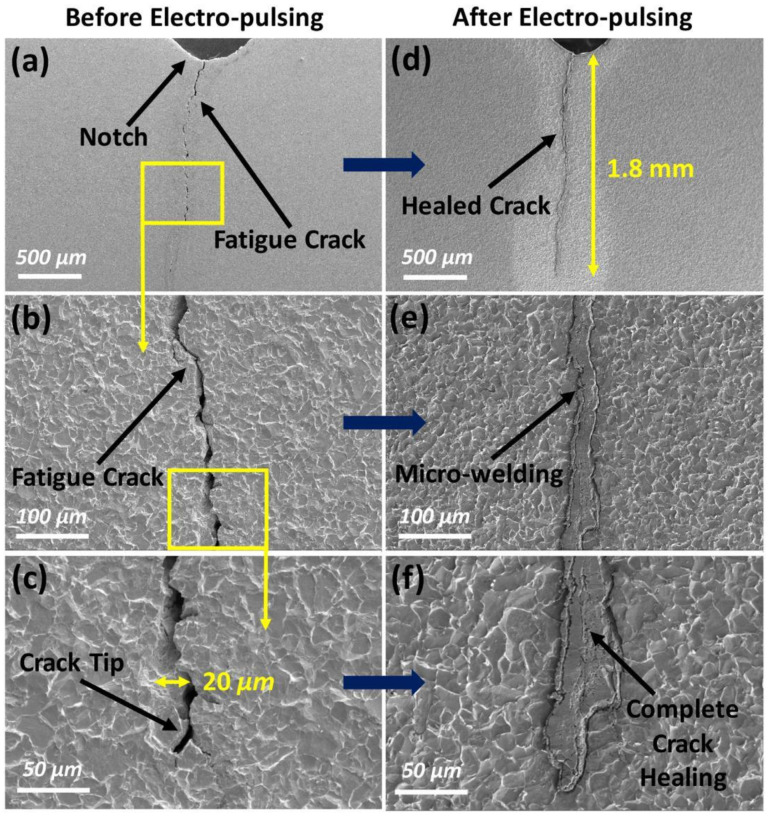

Image of self-healing concrete (Source: Self-Healing Concrete as a Prospective Construction Material: A Review )

The Roman method is but one of many ways to create self-healing concrete. A 2022 report published by the National Center for Biotechnology Information presented an overview of several modern techniques, including concrete mixed with microcapsules of gelatin and epoxy resin that rupture upon contact with cracks, filling in damaged areas.

Another intriguing method deploys organic bacterial cells that generate calcium carbonate, a process that mirrors how aquatic corals are formed and can enable cracked concrete to regain up to 90% of its original strength. This “bio-concrete” method has the added benefit of absorbing CO2. This, along with the material’s ability to reduce waste and increase the lifespan of the built environment, make self-healing green concrete an attractive prospect for those concerned about sustainability.

Though not yet widely used, self-healing concrete remains the subject of ongoing research, and is being actively pursued by the US military.

Solar Glass

Solar panels are excellent sources of clean and renewable energy, but their sheer bulk and opacity can make them an unsightly or even unfeasible addition to certain building projects.

An emerging technology promises to make this problem disappear by transforming windows into sources of power, seamlessly blending electrical solar capacity into clear panes of glass.

Several examples of solar glass technology have sprouted up across the map in recent years. Researchers at MIT have created a solar window called UE Power, a product around which they’ve built a company called Ubiquitous Energy. The small, 14 to 20 inch windows are completely transparent and capable of converting invisible ultraviolet and infrared light into electricity.

Another intriguing example is AuREUS, a solar window that won its inventor the first James Dyson Award for Sustainability in 2020 and may be more than twice as powerful as conventional solar photovoltaic cells. That inventor: Carvey Ehren Maigue, a 27-year-old student at Mapúa University in Manila, Philippines who used luminescent particles derived from rotten vegetables to develop sheets of colorful transparent material that can convert sunlight into electricity.

Like UE Power windows, AuREUS can capture invisible ultraviolet light, even when exposed indirectly on a cloudy day. By contrast, conventional solar panels only work when exposed directly to visible sunlight in clear conditions. What’s more, AuREUS appears to be remarkably efficient: Preliminary tests, according to Maigue, indicate that his invention can produce energy 50% of the time compared to the 15 to 22% of conventional panels.

“We can use AuREUS instead of typical glass windows so that whole buildings can become solar energy farms,” Maigue said in an interview with Dyson. “AuREUS could become part of our clothes, our cars, buildings, and our houses.”

Transparent Wood

That’s right, transparent wood.

It may sound like the stuff of solarpunk sci-fi, but recent research has demonstrated that transparent wood is very much a real world technology that could someday replace glass as the preferred material for windows and other see-through surfaces.

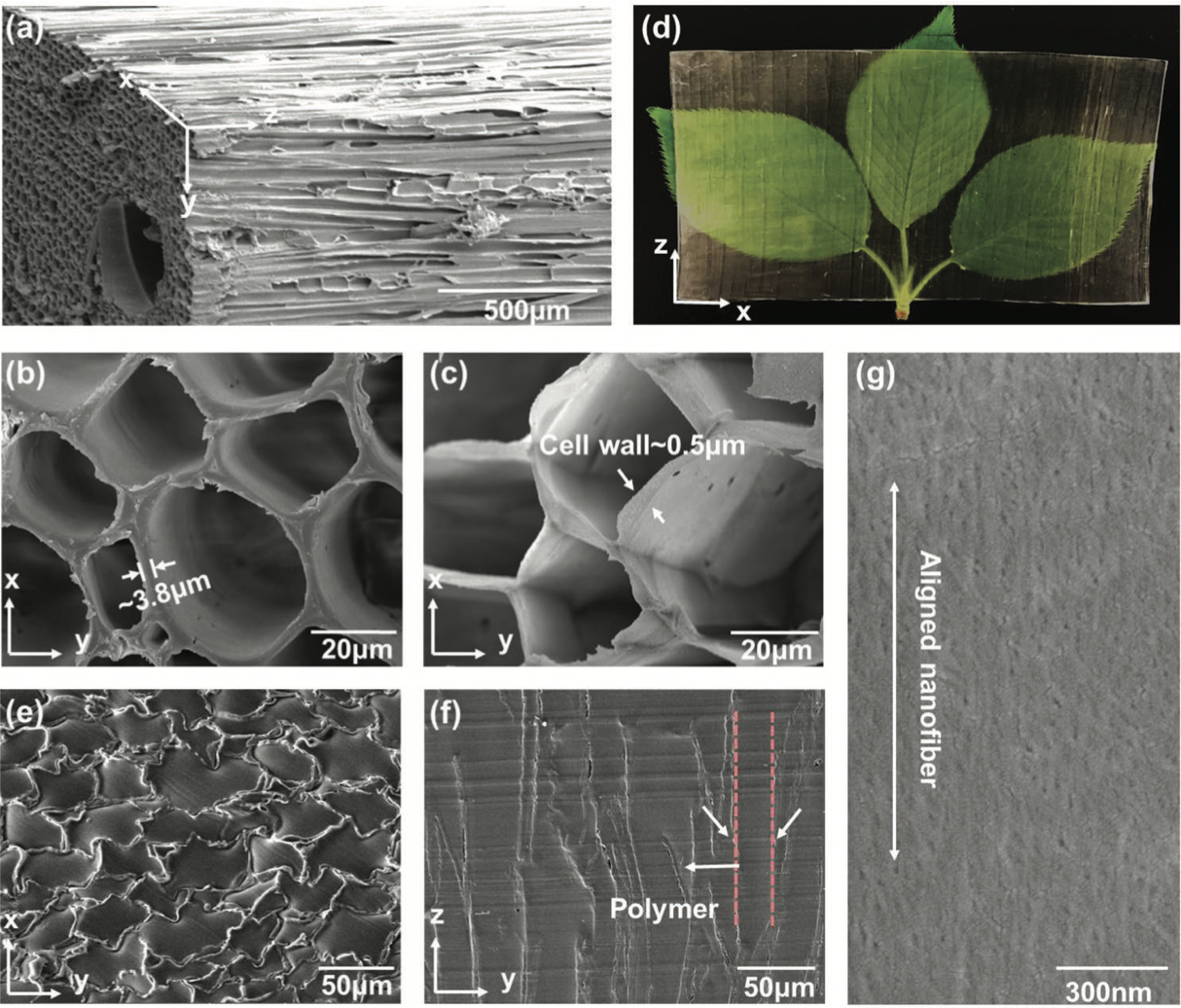

In a 2016 paper, scientists described removing the lignin (the polymer that gives plants their rigidity) from a 1.22 millimeter thick sample of dehydrated balsa wood and replacing it with a solution of prepolymerized methyl methacrylate, an acrylic alternative to glass. The result was a product similar to glass, albeit hazier, ideal—the study said—for transmitting natural light while maintaining privacy. Another paper from 2020 describes a similar process with similar results.

Invented in 1992 by German scientist Siegfreid Fink, transparent wood has many qualities to recommend it. Compared to glass, transparent wood is much lighter and more durable, bending and splintering rather than shattering on impact.

Image of microscopic wood structure and a sample of transparent wood. (source: A Clear, Strong, and Thermally Insulated Transparent Wood for Energy Efficient Windows)

Transparent wood is also much more energy efficient. Roughly 25 to 30% of the energy used to heat and cool our homes leaks out through glass windows, translating to billions of dollars in wasted energy every year. By comparison, transparent wood has five times the thermal capacity of glass, according to the United States Department of Agriculture, making it ideal for sustainable construction.

Transparent wood can also be harvested sustainably, whereas the production of glass is a resource and carbon intensive affair, requiring the mass-extraction of sand (the second most scarce material on the planet) and producing roughly 25,000 metric tons of CO2 per year.

Transparent wood is still in an early phase of development, but it may not be long before you buy your windows at the lumberyard, with solar generating capacity woven into the grain.

Bottom Line

It will take a diverse array of strategies and tactics deployed all at once to both prevent and adapt to the effects of climate change. Nature is a powerful ally in our struggle, but so is human ingenuity. It’s essential that the construction industry begin to transition to renewable materials, but it’s clear that high-tech materials dreamt up in the lab also have a major part to play in building a greener future.